Commercial Bronze

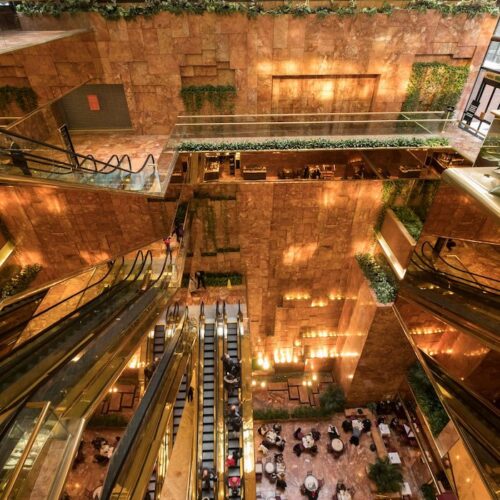

Commercial bronze is a copper alloy composed of 90% copper and 10% zinc and commonly polished for uses across a range of industries. It has a reddish appearance from the high copper content, compared to the lighter shades for other “red” metals such as Muntz Metal or Brass. While not as common in the architectural industry, polished bronze is commonly used in elevator and escalator projects.

At Polished Metals, we provide a wide variety of high-quality finished bronze products, including sheet metal, tubing, channels, angles, and plates. Click here for available bronze sheet metal sizes.

What Is Polished Bronze?

Compared to traditional bronze, polished commercial bronze is an easily machinable grade commonly available in round, square, and rectangular bars & tubes, angles, channels, as well as custom extruded shapes. Polished or satin finished bronze is also frequently used in sheet metal form, both for its unique appearance and color (including the shifting appearance as it ages), as well as for its durability and resistance to corrosion.

Bronze Use Cases

Bronze is commonly used in a wide variety of industries. Where the classic “silver” appearance of metal is effectively served by aluminum and stainless steel, bronze offers an elegant appearance that is not easily replicated by other metals. It also features unique qualities due to its composition, in particular the inclusion of copper.

Here are a few industries where polished bronze is frequently seen:

- Architecture & Design – Bronze is commonly found on buildings, both for exterior features and interior design. Bronze sheet metal may be used for ceiling and wall panels, for elevators and escalators, as well as for exterior cladding.

- Artwork – The use of bronze for artwork dates back thousands of years, and it’s truly a metal that has stood the test of time within fine art. Many sculpture artists still favor bronze over other metals due to its unmatched elegance.

- Hardware & Manufacturing – Various hardware items continue to be made from bronze, including springs, gears, fasteners, and numerous engine parts and machine components.

Qualities of Bronze

Bronze has a variety of qualities that make it a useful metal in many use cases. Some of its notable qualities include:

- Strength: Though not as strong as steel, bronze beats out many other metal types.

- Corrosion resistance: Bronze is often chosen for projects where exposure to the elements is likely.

- Conductivity: Bronze is a relatively good conductor of heat and electricity, though nowhere near as conductive as pure copper.

- Appearance: This metal’s unique color makes it the only choice for some designs.

Cleaning Bronze

Dirt, grime, fingerprints, and slight traces of oxidation can be removed from polished bronze using a solution made up of 50% lacquer thinners and 50% water. Be sure to clean the panels only with the direction of the grain, never against the grain. You will need to use a lint-free cloth for bronze sheet metal cleaning, then rinse the panel using clean water, and wipe with a dry lint-free cloth to dry.