Muntz Metal / Naval Brass

Muntz metal and naval brass are copper alloys composed of 60% copper and 40% zinc. They have a rich golden color and are widely used in the architectural industry for elevator cabs, entrances, revolving doors, swing doors, and storefronts just to name a few. Muntz and naval brass were developed for use in marine environments due to their resistance to corrosion from seawater and brine solutions.

At Polished Metals, we’re a leading supplier of finished Muntz metal and naval brass, including sheet metal, plates, and more. Click here for available sheet sizes.

About Muntz Metal and Naval Brass

Muntz metal and naval brass are both alloys of copper comprising approximately 60% copper and 40% zinc in composition. Despite the difference in name, both of these metals are considered types of brass. Muntz is named for George F. Muntz, who originally invented this alloy. Naval brass was developed afterward specifically for use in marine environments.

Both Muntz metal and naval brass are typically grouped together due to their similar compositions. The primary difference between the two is that naval brass includes a small amount (typically <1%) of tin in addition to copper and zinc.

Typical Uses by Industry

These metals were originally developed for use in marine environments, including for shipbuilding and parts, as well as for use in structures located along the coast. Due to their composition, they stand up well against the harsh salty air and seawater of these environments.

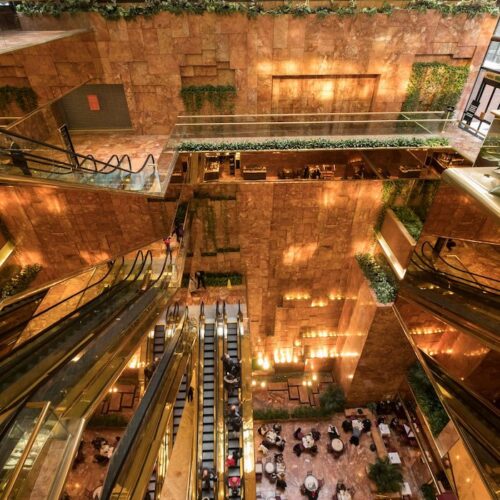

Today, Muntz metal and naval brass see broader use in architectural projects as well. Their gold-like appearance lends a unique aesthetic that is highly favored in many architecture and design projects, particularly for decorative interior elements. These metals may commonly be seen for use in elevators, including cabs, interiors, and ceiling and wall panels.

Muntz and naval brass may also be used for elements that are both decorative and functional, such as railings, trim, and more.

Does Muntz Metal Tarnish?

All copper-based alloys have a tendency to tarnish with age, including Muntz metal and naval brass. Tarnishing is caused by oxidation from exposure to air. In order to keep them in good condition, it’s necessary to clean off tarnish and polish your objects as needed. Many customers choose to lacquer their brass/bronze products to prevent tarnishing.

Cleaning Muntz Metal / Naval Brass

Dirt, grime, fingerprints, and slight traces of oxidation can be removed using a solution made up of 50% lacquer thinners and 50% water. Be sure to clean the panels only with the direction of the grain, never against the grain. You will need to use a lint-free cloth for the cleaning, then rinse the panel using clean water, and wipe with a dry lint-free cloth to dry.

Reach Out to Polished Metals for a Quote!

At Polished Metals, we’ve provided in-house metal finishing and polishing services for more than 40 years covering a wide range of metals. We provide consistent quality on all metal types, finishes, and products serving a broad range of use cases across industries from architecture to automobiles.

Our decades of experience and 50,000 square foot metal finishing facility gives us gives us the attention to detail and bandwidth to process high volumes of metal with supreme quality, every time. If you’re interested in a quote for your project or have questions about custom metal finishing, please reach out to us!