Copper

Copper is a unique metal known for its vibrant reddish color, resistance to corrosion, and use in various alloy metals such as brass and bronze. On its own, polished copper remains popular across various industries, as both its appearance and conductive properties make it ideal for certain use cases. Polished copper may be seen most commonly as sheet metal or in products such as tubing, pipes, and plates.

At Polished Metals, we process high volumes of copper, producing polished copper products in a variety of finishes, including satin and mirror varieties. Our large in-house metal polishing facility enables us to process high-volume orders, while our decades of experience lends us a high degree of precision, skill, and quality of results. Learn more about our finished copper offerings.

Polished Copper: Use Cases

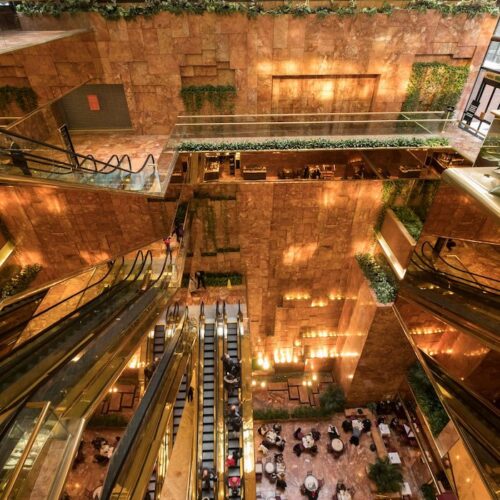

Copper commonly finds use in both commercial and residential settings, across many industries. In many ways, this metal is essential to our daily lives—for instance, copper has long been the preferred metal for nearly all electrical wiring. Generally speaking, copper may be seen in use within the electrical, plumbing, roofing, and ballistics industries, in decorative and ornamental use cases, and occasionally in architectural projects.

What Is Copper Sheet Metal Made From?

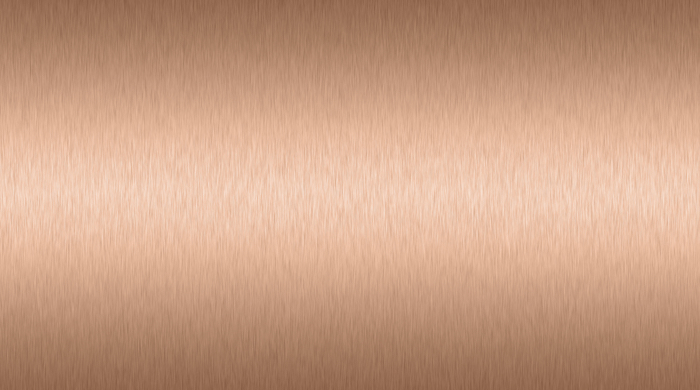

Copper sheet metal, or as it is sometimes referred to as “Electrolytic Tough Pitch Copper,” is a copper alloy composed of 99.6% copper and 0.4% oxygen. It has a reddish appearance from the high copper content. While copper metal is not very popular in the architectural community, save for occasional kitchen range hoods and exterior home decorative trim, it is commonly used for industrial applications in the form of round, square and flat bars. Click here for available sheet sizes.

Cleaning Polished Copper

Dirt, grime, fingerprints, and slight traces of oxidation can be removed using a solution made up of 50% lacquer thinners and 50% water. Be sure to clean the copper sheet metal panels only with the direction of the grain, never against the grain. You will need to use a lint-free cloth for the cleaning, then rinse the panel using clean water, and wipe with a dry lint-free cloth to dry.