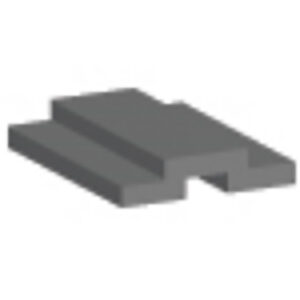

Satin Finishes

We offer the satin finish options listed below across all metal types. To speak with the Polished Metals team about your project, or if you have any questions regarding satin finishing or finish options, request a quote.

What Is a Satin Finish?

In metal polishing, a satin finish is any that results in a surface featuring a more grain-like, brushed, or grooved appearance. While satin finishes still reflect light and produce a gleaming effect, they do not achieve the same high shine as mirror finishes. Satin finishes may be desirable for a variety of reasons, including lower maintenance requirements. In addition, the duller, more matte appearance may be better suited for areas with a large amount of light to reduce glare.