How Is the #6 Satin Finish Produced?

The #6 satin finish is similar to #4, but with an even finer and smoother appearance. After initial polishing, the final finish is achieved by polishing with a 240-320 grit abrasive belt. This results in the finer texture while still maintaining a satin appearance.

#6 Finish Use Cases

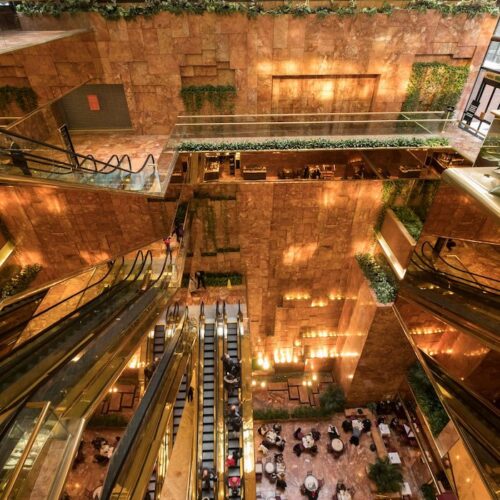

The #6 finish is most often applied to 304 Stainless Steel for use across a wide range of industries. As a practical, low-maintenance satin finish, it is favored for functional use cases in industries including:

- Elevators and Escalators for trim, railings, walls, and more.

- Food and Beverage Industry for appliances, food prep countertops, food and liquid storage, and other areas where metal may come in contact with food and drink.

- Industrial Metals for a wide variety of use cases subject to high safety and cleanliness standards, such as the pharmaceutical industry, manufacturing, brewing, and more.

In addition to stainless steel, the #6 satin finish may be applied to a range of other metals including commercial bronze, brass, architectural bronze, and more.