Aluminum sheet metal is among the most widely used metal products in the world. Whether used as sheets or shaped, bent, twisted, and cut into various other products, the amount of products made from aluminum sheets is nearly endless.

At Polished Metals, our team produces high volumes of polished aluminum sheets in both satin and mirror finishes, covering projects across industries such as architecture, art and design, ornamentation, manufacturing, and so much more. So today, we’re sharing some of our insider knowledge about aluminum sheet metal, including this product’s properties, advantages and disadvantages, use cases, and more.

Why Aluminum? Advantages of Aluminum for Sheet Metal

Polished aluminum makes an ideal metal for sheets due to many factors:

- Aluminum is lightweight compared to most others, while still retaining an impressive strength-to-weight ratio.

- Aluminum is readily malleable and amenable to any sort of forming, making aluminum sheets an ideal starting point for projects where specialized shapes are needed.

- It is also very resistant to corrosion, making it a well-rounded choice of metal that also tends to be available at a more affordable price point.

Key Considerations: Disadvantages of Aluminum

While aluminum sheet metal is incredibly versatile, as we’ll cover when we review its use cases, there are also some reasons why it may not be the best choice for certain applications. The primary disadvantages of aluminum sheet metal include its lesser sheer strength compared to metals like stainless steel; its greater susceptibility to cosmetic damage, such as dents and scratches; and its high thermal conductivity, which can lead to challenges with heat and welding.

In other words, where aluminum’s many advantages make it the favored choice for a wide range of applications, there are definitely times where other metals make more sense to use.

Aluminum Sheet Metal Finishes

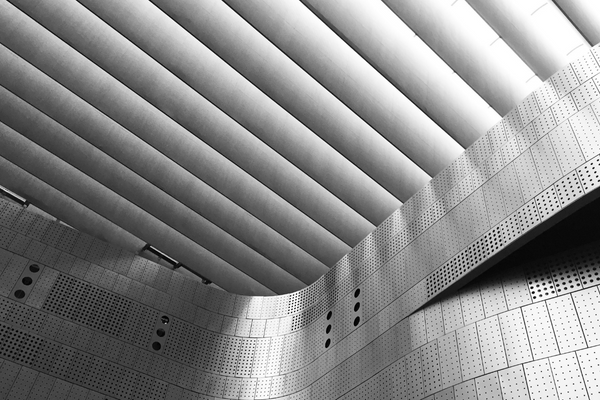

Another major advantage of using aluminum for sheet metal is this metal’s ability to take on a wide range of finishes to suit the needs of any project. Aluminum sheet metal is available in everything from high mirror finishes, ideal for aesthetic applications such as artwork and architecture, as well as satin finishes for practical use cases.

Use Cases for Aluminum Sheet Metal

We recently covered the many things aluminum is used for overall. As with aluminum on the whole, the uses of aluminum sheet metal are wide-ranging, including:

- Exterior cladding, including anti-vandalism cladding

- Flashing and roofing

- Storefronts, facades, and entryways

- Marquees and other signage

- Elevator parts, especially elevator interiors for wall and ceiling panels

- Interior design, including wall and ceiling panels

- Forming into ductwork and other shapes

- Packaging

- Automobiles

- Aerospace projects

Is Aluminum Cheaper Than Stainless Steel?

Generally, aluminum sheet metal will cost less than stainless steel. This is another advantage that aluminum sheet metal can provide.

However, if strength is critical to your project, the difference in cost will be more than made up for in the structural integrity that stainless steel can provide.

Learn More About Our Aluminum Offerings

Aluminum sheet metal is available in a wide range of sizes and specifications to suit the needs of industries and projects. At Polished Metals, our 50,000 square foot facility means we’re able to maintain a large inventory of metal products, and sheet metal in particular.

Our available sheet metal comes in an array of sizes. You can review our offerings on our sheet metal page, including aluminum and other metals.

Or if you’re ready to start your project, reach out today for a quote!