If you ask anyone to picture “metal” in their head, chances are they’ll imagine aluminum or stainless steel. Both aluminum and stainless steel are perhaps most commonly seen metals in our day-to-day life—and two of the most commonly used finished metals worldwide. Yet while these metals may look similar, their properties are quite different—and many individuals will face a tough choice in comparing aluminum vs. stainless steel for their project.

As leading experts in the metal finishing industry, our team at Polished Metals routinely works with both aluminum and stainless steel across various products, projects, and industries. Both of these materials have incredible versatility and utility depending on the demands of your project. So today, we’re providing a full comparison of these metals to help you in evaluating aluminum vs. stainless steel for your project.

Aluminum vs. Stainless Steel: Compositional Properties

Before evaluating the properties of these metals, it’s important to understand their unique compositions.

Let’s begin with stainless steel. In the simplest terms, stainless steel is an alloy of iron, carbon, and chromium. This addition of chromium to the typical steel composition of iron and carbon lends the metal improved strength and greatly increased resistance to corrosion—giving it the “stainless” name.

Stainless steel may vary from this essential composition in many different ways. Specific alloys such as 304 stainless steel (the most common), as well as 316, 430, and many others contain varying amounts of chromium and/or additional metals (such as nickel or molybdenum).

Unlike stainless steel, aluminum is not an alloy by default, being an elemental metal that is naturally occurring. That said, pure aluminum is generally too soft and weak to be used in commercial applications.

Instead, aluminum is augmented with trace amounts of other metals; depending on the specific type, aluminum may include copper, silicon, iron, or zinc, among others. That said, commercial aluminum is still 99% to 99.6% pure.

Comparing Aluminum and Stainless Steel

Despite similar appearances (which we will discuss below), stainless steel and aluminum possess very different characteristics. In deciding between aluminum vs. stainless steel, it is important to carefully consider the demands and needs of your project and evaluate how each quality fits in.

Here’s how aluminum and stainless steel stack up across various dimensions.

Strength & Weight

Stainless steel is renowned as one of the strongest metals in the world, and therefore it should come as no surprise that it generally outperforms aluminum in terms of sheer strength. Stainless steel possesses both better tensile strength and greater resistance to impact damage compared to the more malleable aluminum.

That said, much of stainless steel’s strength is due to its comparatively high density. By volume, aluminum is much lighter than stainless steel, which is critical in the manufacturing of various products. In addition, aluminum actually boasts a greater strength to weight ratio than stainless steel.

Conductivity & Heat Resistance

Aluminum is an excellent conductor, of both electricity and heat. Stainless steel, on the other hand, is a very poor conductor of both, and therefore a better insulator. By that same token, however, stainless steel can tolerate much higher temperatures without warping, while aluminum may become misshapen under high-heat conditions.

Corrosion Resistance

Both stainless steel and aluminum are well known for their excellent corrosion resistance. Aluminum does not rust (as it contains no iron); despite popular believe, stainless steel can under certain conditions.

However, when exposed to other harsh, corrosive conditions, stainless steel generally performs better. This includes exposure to corrosive chemicals (acidic or basic) or marine environments, both of which can damage aluminum. While there are more corrosion-resistant aluminum alloys out there, stainless steel simply offers more resistance by default.

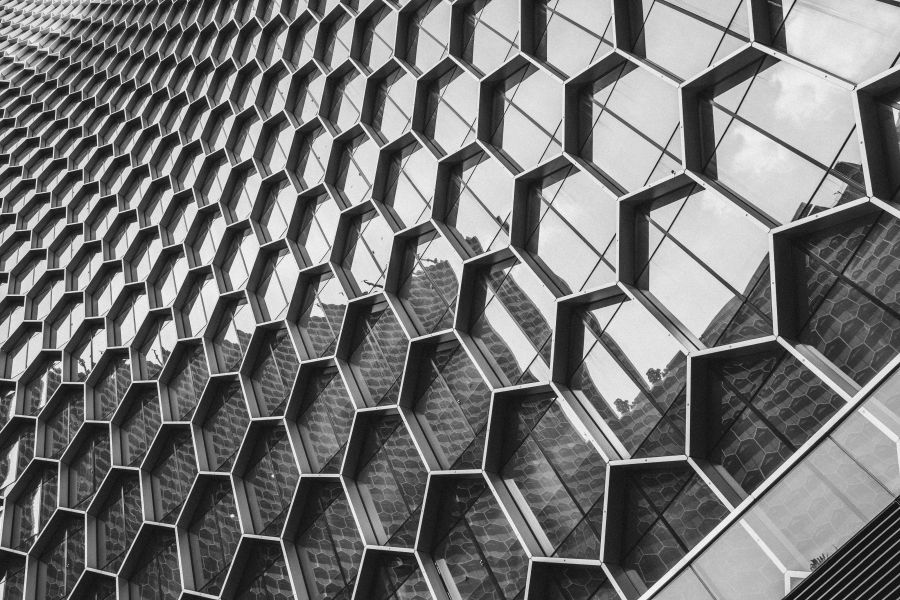

Appearance

Appearance is one area where it can be particularly difficult to differentiate between stainless steel and aluminum. After all, both metals are generally silver in color and each takes well to a wide range of both mirror and satin finishes.

However, the metals are not identical, and a well-trained eye will be able to tell the difference between aluminum and stainless steel. Stainless will generally appear shinier, while aluminum will often have a more grayish tint compared to stainless steel.

Stainless Steel – #8 Mirror Finish

Which Is Better, Aluminum or Stainless Steel?

Comparing aluminum vs. stainless steel can be a challenge, as both metals offer their own clear benefits and drawbacks. What’s more, both metals are commonly used across many of the same industries, including architecture and design, automotive, industry, and more.

Determining whether aluminum or stainless steel is better will depend entirely on the priorities of your project.

Overall, stainless steel is a much stronger and more durable metal compared to aluminum. Its strength is virtually unmatched in the metal finishing industry and its corrosion resistance is similarly impressive. However, stainless is also quite a heavy metal, which can present structural hurdles, and it tends to be more expensive as well per unit volume.

On the other hand, aluminum is more affordable, lighter in weight, and still offers considerable strength and corrosion resistance. For projects that require high conductivity, aluminum is also an excellent choice. That said, aluminum cannot match the strength of steel, nor can it tolerate the same level of corrosion or heat exposure.

For design and ornamentation, both metals can produce a very similar appearance, and while stainless steel can offer a brighter sheen, this may not be worth the tradeoff in weight and price.

Reach Out to Polished Metals to Discuss Your Project

Aluminum and stainless steel are some of the most important metals in the world, both historically and in modern times. Comparing the two is difficult, and the existence of dozens of varieties of each only serves to complicate things further.

Here at Polished Metals, we’re known throughout the world as true experts in metal finishing. Our experienced team works with many forms of aluminum and stainless steel, and we’re happy to lend our expertise in planning your project. No matter what the demands of your project may be, our craftsmen can produce the right volume of high-quality finished metals to meet your needs, all within your timeline and budget.

Reach out to our team today to request a quote or to learn more about our finishing capabilities.